"Ross Kraz" (ropstafer)

"Ross Kraz" (ropstafer)

07/28/2016 at 14:00 • Filed to: Just the Tips, BMW, Starter, E39, M52, Repair

3

3

21

21

"Ross Kraz" (ropstafer)

"Ross Kraz" (ropstafer)

07/28/2016 at 14:00 • Filed to: Just the Tips, BMW, Starter, E39, M52, Repair |  3 3

|  21 21 |

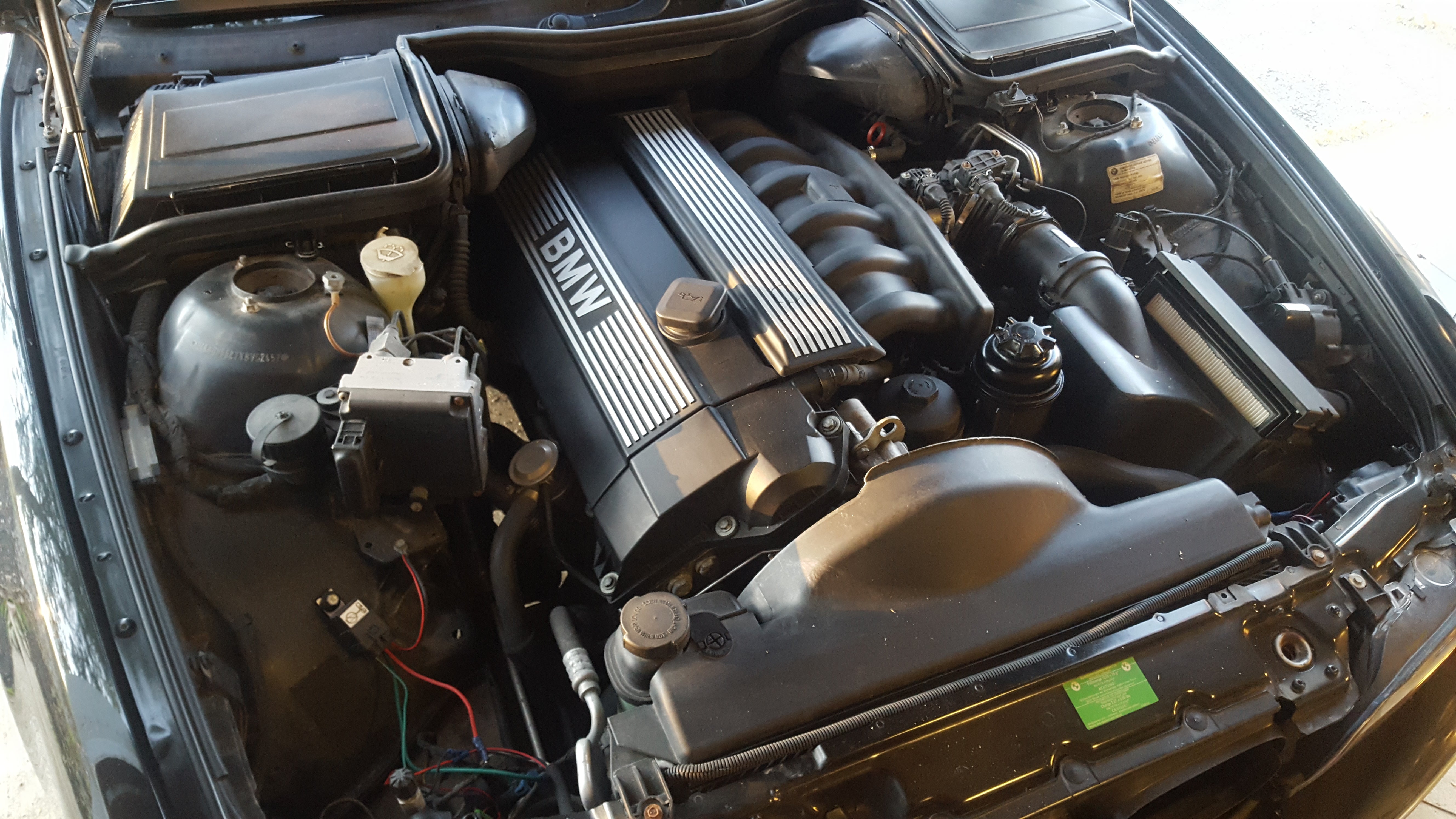

Specifically, on the E39 2.8L M52, but there are a lot of similarities for other engines. This repair is notoriously frustrating, with limited room to work underneath the intake and up against the firewall.

There are a lot of step by step threads and articles on the net which I will link at the bottom for more reading.

Signs and Symptoms

(obviously) Engine not starting. Can be intermittent.

A whirring/whizzing sound as the starter spins but is not engaged

A grinding while cranking can be a warning sign. You may think the flywheel is missing teeth, but the starter cog is designed with a softer material to fail first and, most likely, your flywheel is fine.

What You Will Need

The new starter. Duh, right? But actually, this needs to be mentioned. These are available with either threaded or thru holes. The 2 mounting bolts run through the transmission bell housing and to the starter, where they either thread directly in or will need a nut on the backside. The threaded is recommended to save headaches, but check what is on your car. You may need different bolts. Speaking of which...

Getting new bolts isn’t necessary, but it also isn’t a bad idea. Some sources say they are one-use-only. Technically, all bolts are one-use-only in critical areas in order to get accurate clamping forces. But these bad boys are M12 x 1.50 x 70mm, which isn’t a common thread size that you can find at a hardware store, so you may need to order them ahead of time. Also...

The bolts have an E14 external Torx head , which I didn’t even know existed before doing this. I actually had a hard time finding a set of these sockets at local stores. DO NOT USE A 12 POINT SOCKET. It will strip. (EDIT: The 3 series typically uses a size E12, M10 x 1.25 x 65)

Penetrating oil

Metric wrenches and sockets (8mm, 10mm, 13mm)

Very long (3') socket extension or a u-joint socket, depending on your method

I used a swivel headed socket handle (a ratchet that doesn’t ratchet) like !!!error: Indecipherable SUB-paragraph formatting!!! .

Zip ties to hold hoses and wires out of your way

Method #1: From the Top: Remove the Intake

This method will greatly improve your access to the starter, and will be the easiest to remove the failed part. I chose this method on my E12 because the intake was already removed when I bought the car. I still had to wrestle with wrench access for the mounting bolts and wire connections, and it was difficult to maneuver the part in and out of place.

The problem with this method is the added time and risk involved in further disassembly. If you aren’t careful, more parts could be damaged and end up costing you.

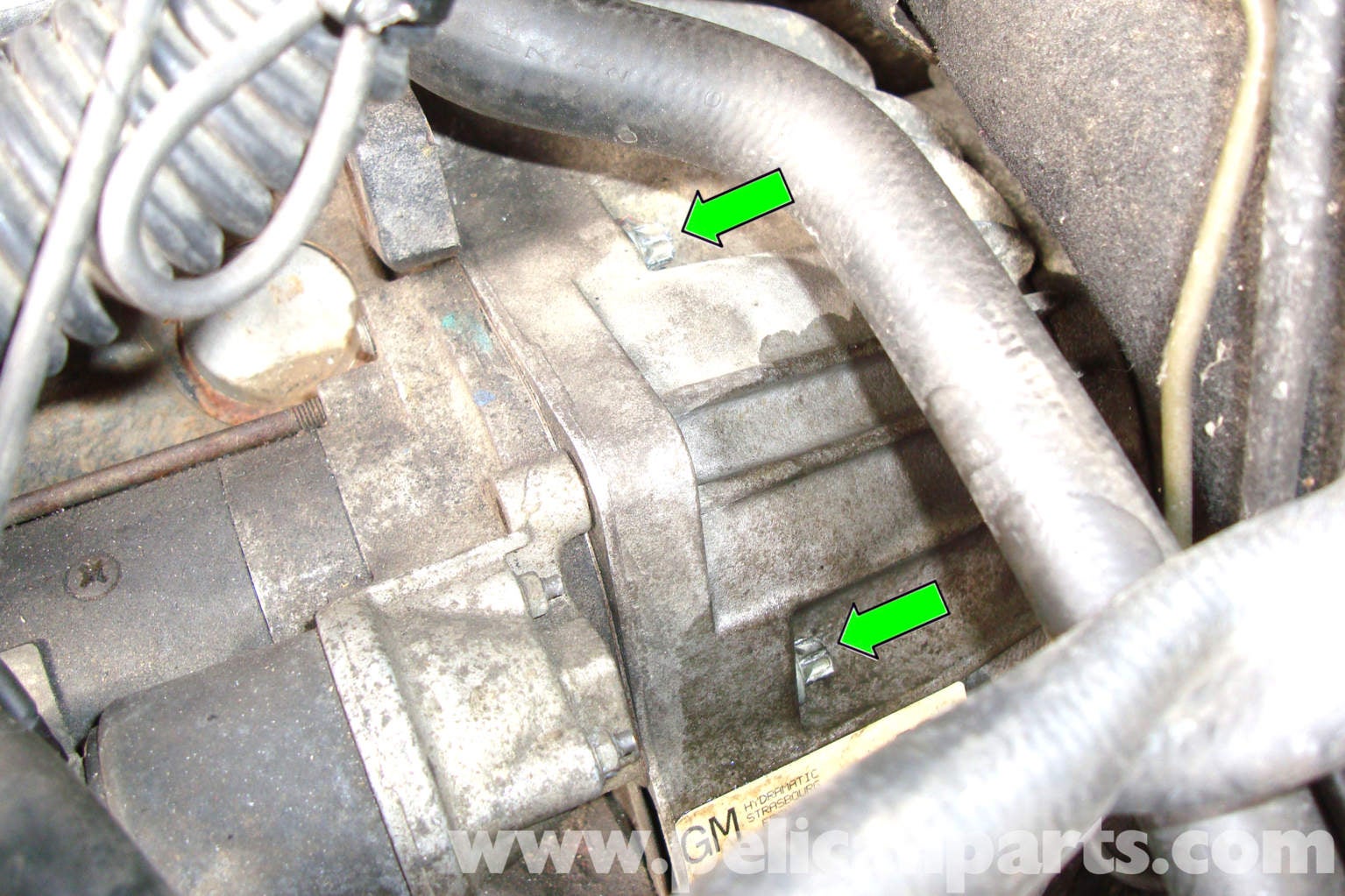

Here’s an image from bimmerfest forums with the intake removed. Note that the top mounting bolt is not pictured and behind that flexible conduit.

Method #2: From Underneath

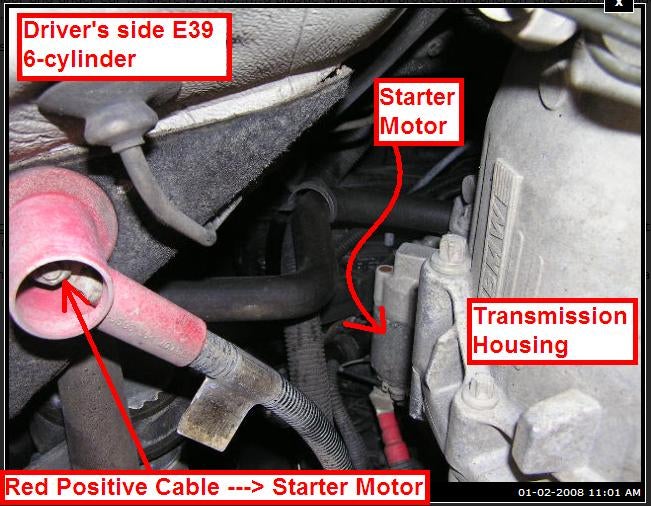

Sort of. From the bottom, you cannot see the top mounting bolt or the top wire connection. I ended up removing the air cleaner box, MAF, and intake boot up to the throttle body, because I had to replace a couple hoses for the idle control valve anyway. It was also a huge help to remove the duct that runs from the driver-side cabin air filter to the firewall. That gave me access to the bolt from the top.

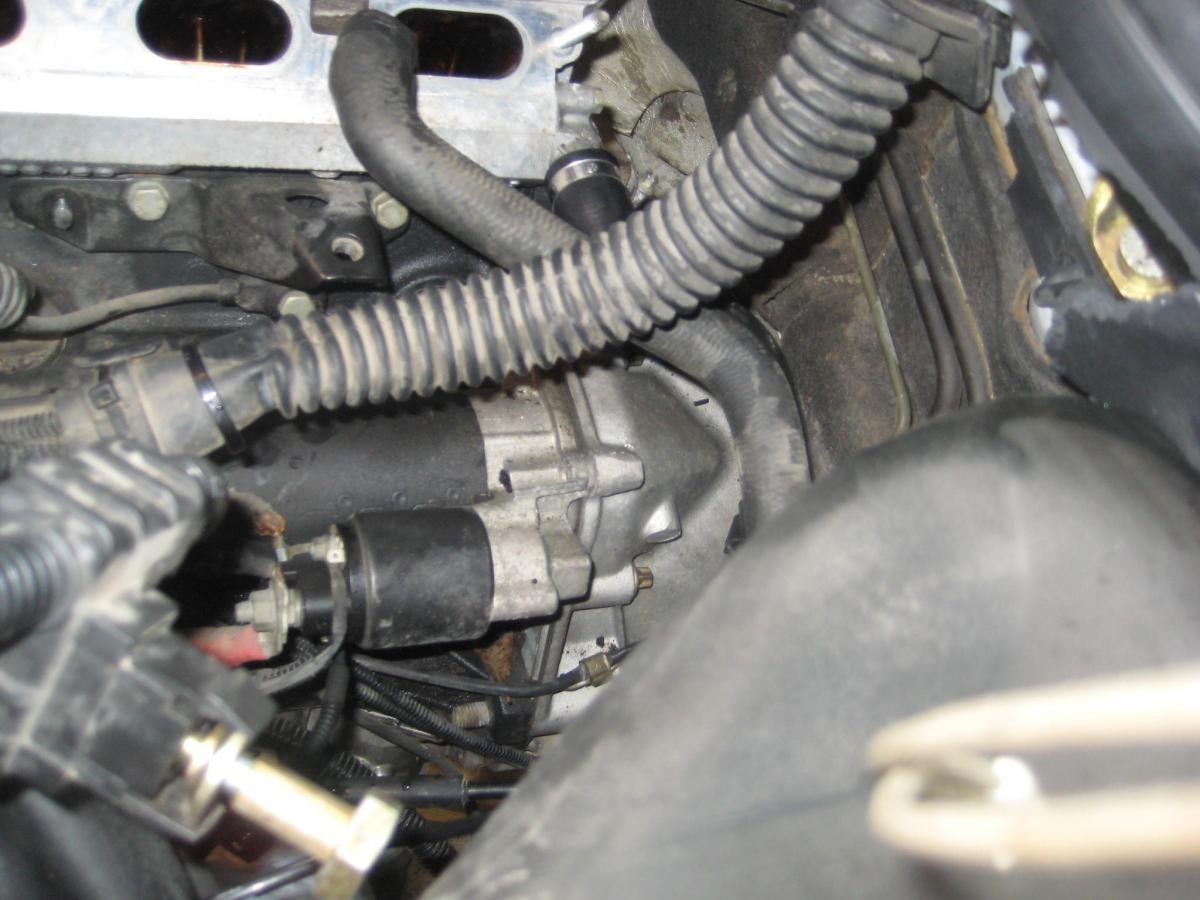

While under the car, you will still be battling the subframe, suspension components, and the steering column. Falling wrenches hurt.

It goes without saying that you will need a jack and jackstands for this method. I had to build some !!!error: Indecipherable SUB-paragraph formatting!!! to get my jack under the car, because my jack is not low profile. You may also need those really long extensions, but more on that later.

A view from the bottom via bimmerfest forums

Method #3: Don’t

Go to a trusted mechanic or dealership. This repair is a giant pain in the ass as a DIY. The downsides here are that it will cost you with part mark-ups, around 3 hours of labor, and possibly a tow to the shop. You might be able to avoid the tow truck with a bump start (if you have drive stick) or by hitting the solenoid with a hammer to try and get it to engage.

So how do you actually get that old starter out?

First, disconnect the battery. Then remove anything that will help you get better access. Then, have any of your stress-relieving methods at hand, whether they be mental, physical or liquid.

There are 4 wires that connect to 3 posts on the starter. Each is a different size, which helps when you go to put the new one on. On the new part that I had, which came with the car, the smallest stud (for the solenoid ground, on the top of the solenoid) was a bit too long. It made it very difficult to get the little 8mm nut on while peering through the intake to see it. A magnet helped, but I still dropped it a dozen times. The rest were pretty straight-forward.

Now, let me talk about those external torx head mounting bolts. Here are the difficulties that you face:

Cramped space, limited visibility

Surrounding components that inhibit wrench alignment and motion

The bell housing will not allow an average socket wrench to fit over the head straight, so you need an extension, but...

You are too close to the firewall to use even a 3" extension

So, most write-ups call for 3 feet(!) of socket extensions. The extensions can travel down the tunnel along the side of the transmission until you have enough space to turn the wrench somewhere around the driveshaft.

I did not have 3' of extensions. My method used a universal joint socket. Even with that, my socket wrench could not fit because of the aforementioned bell housing, so I used a swivel headed socket handle (side note: I did try using this socket handle directly onto the bolt without the universal joint but it was still too large and hit the bell housing).

This combo can be frustrating to get it lined up and allow the transfer of torque, but it can be done. A piece of pipe is necessary for leverage. I used the handle for my jack. All the while, you are up to your shoulders in the engine bay and trying push hoses out of the way so you can turn the wrench.

Possibly, a set of deep-well external torx sockets would be able to get in there. Or a set of torx wrenches. Maybe. I cannot confirm that, nor could I find those anywhere locally.

You drop the old part through the bottom, and that’s it. Just 2 bolts and 3 wire studs. Sounds easy, right?

This was one of those times where the frustration to satisfaction ratio was very bad. Then I remembered how much money I’d saved over bringing it in, and I felt a little better. Of course, then I drive it and I forget why I was mad in the first place.

Additional Resources:

https://www.youtube.com/watch?v=LW02cH…

https://www.youtube.com/watch?v=M6OKvV…

http://www.pelicanparts.com/BMW/techarticl…

http://www.bimmerforums.com/forum/showthre…

http://www.bimmerfest.com/forums/showthr…

http://www.bimmerfest.com/forums/showthr…

Party-vi

> Ross Kraz

Party-vi

> Ross Kraz

07/28/2016 at 14:08 |

|

What an absolute cluster fuck of a repair.

Ross Kraz

> Party-vi

Ross Kraz

> Party-vi

07/28/2016 at 14:18 |

|

Oh, absolutely. There are times, usually routine maintenance, where the genius of BMW design shines through. Then there are times like this when you wonder what circle of hell the engineer will be in for approving this.

StoneCold

> Ross Kraz

StoneCold

> Ross Kraz

07/28/2016 at 14:18 |

|

Would this be an inappropriate time to state “Shoulda gotten a V8?”

functionoverfashion

> Ross Kraz

functionoverfashion

> Ross Kraz

07/28/2016 at 14:22 |

|

There’s one more I’ve read that you might want to include if the Kinja gods will let you... good write-up in any case. I’m dreading this if I have to attempt it on my E46.

http://www.bimmerfest.com/forums/showthr…

Party-vi

> Ross Kraz

Party-vi

> Ross Kraz

07/28/2016 at 14:23 |

|

They lost the war(s) so this is how they get back at us.

Ross Kraz

> StoneCold

Ross Kraz

> StoneCold

07/28/2016 at 14:25 |

|

No, but then this thread would have been about a water pump or timing chain tensioner...

functionoverfashion

> Ross Kraz

functionoverfashion

> Ross Kraz

07/28/2016 at 14:28 |

|

My favorite example of good design in this era of BMW is the headlight bulb access. I was on a road trip and lost a low-beam bulb. I stopped for fuel, popped the hood, swapped out the high beam bulb for the low beam (dead) bulb - with NO TOOLS - finished before the gas was done pumping, and continued on my merry way. I probably also checked the oil while I was in there.

This is something that is so common, but far too often

incredibly complex,

sometimes requiring the removal of several large components, or things like a front wheel and wheel arch. BMW definitely got that one right in my E46.

Also the top-mounted cartridge oil filter. LOVE that one.

StoneCold

> Ross Kraz

StoneCold

> Ross Kraz

07/28/2016 at 14:31 |

|

Excellent come back!

Ross Kraz

> functionoverfashion

Ross Kraz

> functionoverfashion

07/28/2016 at 14:35 |

|

That looks pretty similar to what I did actually, by removing a lot of stuff from the top, but definitely more detailed explanation of troubleshooting and disassembly.

It is worth noting, though, that the 3 series uses size E12 bolts instead of the E14 like the 5 series.

Thanks for sharing!

Ross Kraz

> functionoverfashion

Ross Kraz

> functionoverfashion

07/28/2016 at 14:40 |

|

The oil filter is ok, if you have the socket to get it open lol either way it’s better than a screw on filter that always makes a mess.

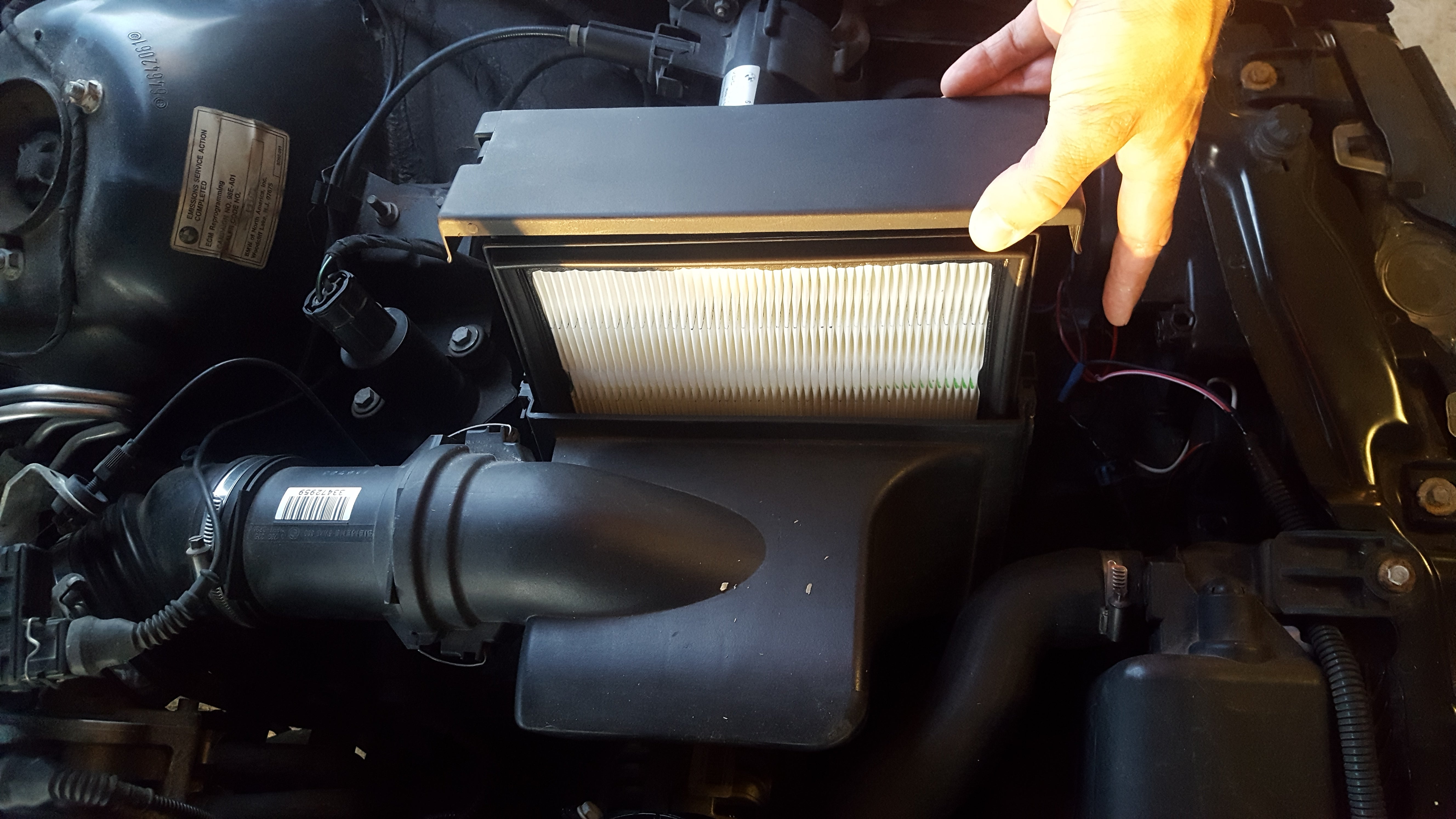

My favorite so far is the air cleaner that just slides in with a satisfying click:

If only EssExTee could be so grossly incandescent

> Ross Kraz

If only EssExTee could be so grossly incandescent

> Ross Kraz

07/28/2016 at 14:41 |

|

Bookmarked for hopefully not future use

RallyWrench

> Ross Kraz

RallyWrench

> Ross Kraz

07/28/2016 at 14:43 |

|

Without a lift, it’s easier from the top. If you’re on your back under the car it’s hard to get the angle on it. It’s really not hard to take the intake off. Remove the cabin air duct with a 1/4 turn, pull the fuel rail cover to get access to the 02 sensor wiring, disconnect the throttle housing plug and cam and crank sensor plugs under the manifold, move the dipstick and PCV drain hose, disconnect the valve cover breather pipe, disconnect and plug the fuel lines, and off you go. While it’s off it’s a good idea to replace the PCV separator under the front of the manifold, it takes minutes with it apart and is otherwise a pain in the ass. I have a really long 1/2" drive extension (like 3 feet) that works great for getting the top bolt over the trans. There’s a brace under the intake that can be removed to give you a little more wiggle room too.

Ross Kraz

> RallyWrench

Ross Kraz

> RallyWrench

07/28/2016 at 14:52 |

|

I like how you say “easier” as if the other way is easy to begin with.

Morale of the story: take off a bunch of shit and get the right tools

RallyWrench

> Ross Kraz

RallyWrench

> Ross Kraz

07/28/2016 at 14:55 |

|

Well, I’ve only done about 200 of them, so “easy” is a relative term. The right tools and access are the key. You have to take much less shit off from the bottom, but you really need a good angle of attack, so to speak. Doing them from underneath on the ground would suck. On a lift, it’s the only choice for me. Fun fact: On the newer N-series engines, it can’t be done without taking off the intake.

Santiago of Escuderia Boricua

> Ross Kraz

Santiago of Escuderia Boricua

> Ross Kraz

07/28/2016 at 16:54 |

|

I think the starter on mine is going as well. Any big difference on an e36?

Ross Kraz

> Santiago of Escuderia Boricua

Ross Kraz

> Santiago of Escuderia Boricua

07/28/2016 at 17:19 |

|

Pretty much. That top link is a (not all that helpful) video for an e36 and the last link is for an e46. Haven’t done one personally but from those it looks very similar. I couldn’t find much on mine so I read through some forums on 328's.

The bolts on the starter are smaller and shorter (E12 torx head). Other than that, it’s pretty much the same.

I was able to get by with just taking off some air hoses/ducts and using only most of the right tools, but it was a pain. TFritch’s comments sums it up best. You need access and you need the right tools.

Ross Kraz

> StoneCold

Ross Kraz

> StoneCold

07/28/2016 at 17:20 |

|

You see that Deadspin article about you?

Ross Kraz

> Santiago of Escuderia Boricua

Ross Kraz

> Santiago of Escuderia Boricua

07/28/2016 at 17:39 |

|

Also, try cleaning up battery terminals and wires on the starter, first. It will crank slow if you have a bad connection.

Santiago of Escuderia Boricua

> Ross Kraz

Santiago of Escuderia Boricua

> Ross Kraz

07/28/2016 at 20:05 |

|

Seeing as how I’ve removed the intake three times in the last two weeks, I’m pretty comfortable with it.

The starter sometimes, when warm, makes the whirring noise like it’s not engaging. Cold start always works though... Not really ideal for a race car

Ross Kraz

> Santiago of Escuderia Boricua

Ross Kraz

> Santiago of Escuderia Boricua

07/29/2016 at 00:10 |

|

Well shit then next time you have it off just go for it lol electric stuff doesn’t like heat so it could be something with the solenoid. Like when it’s hot out and my sunroof won’t open til it cools off...sort of.

jimz

> Ross Kraz

jimz

> Ross Kraz

09/06/2016 at 03:26 |

|

The bolts have an E14 external Torx head ,

BMW: “Why? Because fuck you.”